Products

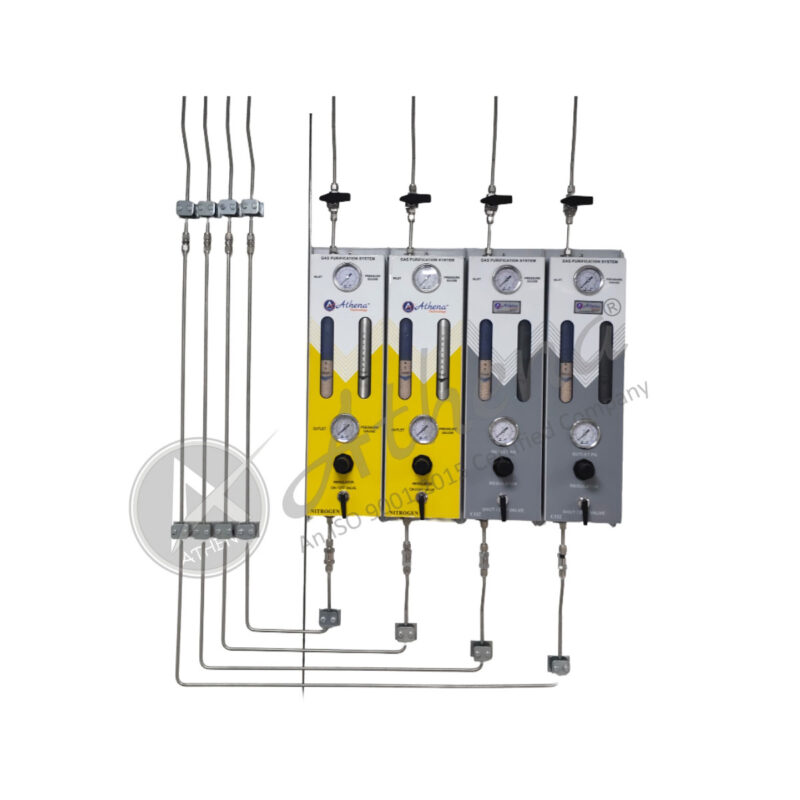

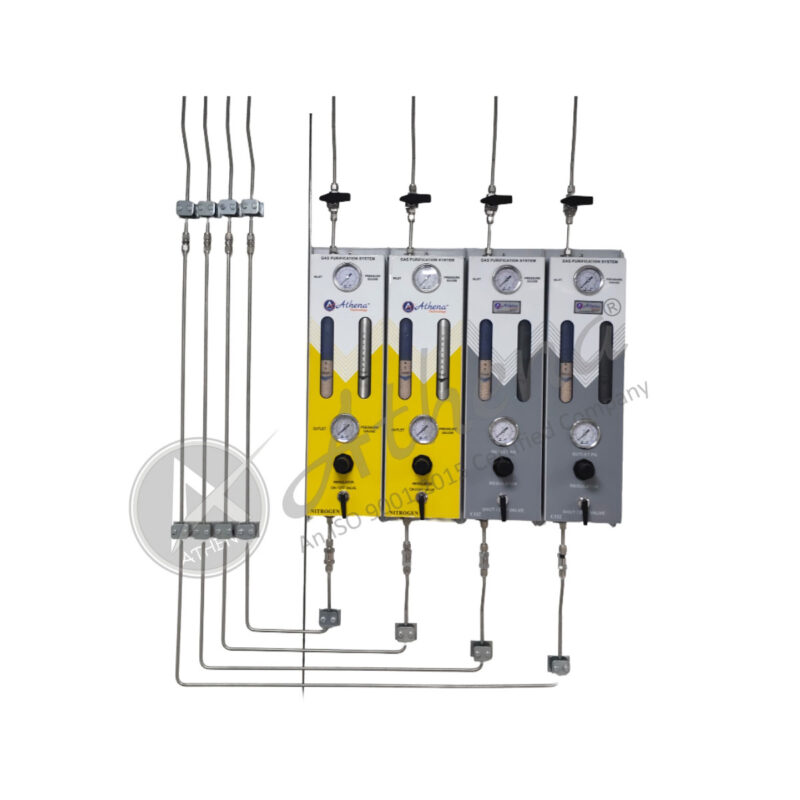

Gas Purification Panel & Control System

Ultra-High Purity Gas Delivery for Analytical Excellence

Athena Instruments introduces the Gas Purification Panel & Control System—a robust, precision-engineered solution designed for the safe, efficient, and reliable delivery of ultra-high purity (UHP) gases essential for Gas Chromatography (GC), ICP, AAS, LC-MS-MS, GCMS, ICP MS and other analytical systems.

Crafted using high-quality materials and advanced filtration technology, Athena’s system ensures consistent removal of critical impurities including moisture, oxygen, hydrocarbons, and particulates. The result: cleaner gas lines, improved instrument lifespan, reduced maintenance costs, and highly reproducible analytical results.

Available in standard and custom configurations with international safety certifications, the Gas Purification Panel & Control System is your dependable partner for demanding laboratory environments.

Key Features :

- High-Grade Construction: Powder-coated wall-mounted panel with optional full stainless-steel body for enhanced durability and corrosion resistance.

- Precision Gas Purification: Removes moisture, oxygen, hydrocarbons, and particulates to deliver better-than-UHP-grade gases.

- Integrated Safety: Optional safety frames, CE-certified designs, and leak-tight sealing to ensure operator and system safety.

- Flexible Pressure Control: Supports 10 kg/cm² inlet pressure with adjustable 0–7 kg/cm² outlet via precision regulators.

- Easy Serviceability: Modular, easily detachable filters enable hassle-free maintenance and replacement.

- Cost-Effective Operation: Toggle valves and distribution panels reduce gas wastage and optimize usage.

- Customizable Connectivity: Available with 1/4” or 1/8” fittings and tubing in SS, Copper, Nylon, or Teflon.

Applications

Gas Chromatography

(GC)

ICP & AAS

Systems

LC-MS-MS Exhaust Systems

General Laboratory Gas Delivery

Product Models & Specifications

|

Model Name |

Dimensions (mm) |

Weight |

Inlet Pressure |

Outlet Pressure |

Connections |

|---|---|---|---|---|---|

| GPP-01 | 420 W × 600 H × 87 D | 14 kg | Up to 10 kg/cm² | 0–7 kg/cm² | 1/4” or 1/8” tubing |

Laboratories & Research Centers

- Inlet pressure: 10 kg/cm² maximum

- Outlet range: 0–7 kg/cm² with Neoprene/SS diaphragm

- Toggle Valve: On/off type with leak-tight dual-seal design

- Pressure Gauges: Panel-mounted, 0–10 kg/cm²

Tubing Options:

- Materials: Stainless Steel, Copper, Nylon, Teflon

- Smooth bore construction with color-coded sleeves for contamination-free gas flow

Filtration & Purification Stages

- Moisture Removal: Indicating silica gel and molecular sieves (outlet impurity < 3 ppm)

- Oxygen Removal: De-Oxo catalytic materials (outlet impurity < 2 ppm)

- Hydrocarbon Removal: Activated charcoal/carbon filters (outlet impurity < 2 ppm)

- Particulate Removal: Inline stainless-steel micron filters (5–10 µ)

Additional Technical Highlights

Inline Micron Filters:

Essential for capturing fine particles shed by cylinders, protecting sensitive GC detectors.

Activated Charcoal Cartridges:

High-surface-area media for hydrocarbon removal, reducing FID baseline noise.

Silica Gel & Molecular Sieves:

High-capacity, regenerable, with indicating color change for easy monitoring.

De-Oxo Catalysts:

Pre-treated, regenerable, available in indicating/non-indicating options.

Integrated Distribution Panels:

Control gas flow and pressure to multiple instruments with independent settings.

Selector and Changeover Boxes:

Seamless switching between cylinders or gas generators for uninterrupted supply.

Why Choose Athena Instruments Gas Purification Panel & Control System?

Precision Purification

Delivers contamination-free UHP gases essential for accurate, reproducible analysis.

Cost-Efficient Operation

Reduces high-purity gas consumption with precision control and efficient distribution.

Customizable Configurations

Built to your specifications with flexible fittings, tubing, and filtration options.

Responsive Support

Backed by Athena’s technical assistance, including remote and on-site service options.

Enhanced Instrument Life

Protects sensitive GC columns and detectors from moisture, oxygen, hydrocarbons, and particulates.

Field-Proven Durability

Designed for rugged lab environments with high-quality materials and components.

Certified Quality

CE certified, ISO 9001:2015 compliant for global safety and quality standards.

Trusted Performance, Certified Quality

Need help finding a solution?

Gas Purification Panel & Control System

Ultra-High Purity Gas Delivery for Analytical Excellence

Athena Instruments introduces the Gas Purification Panel & Control System—a robust, precision-engineered solution designed for the safe, efficient, and reliable delivery of ultra-high purity (UHP) gases essential for Gas Chromatography (GC), ICP, AAS, LC-MS-MS, GCMS, ICP MS and other analytical systems.

Crafted using high-quality materials and advanced filtration technology, Athena’s system ensures consistent removal of critical impurities including moisture, oxygen, hydrocarbons, and particulates. The result: cleaner gas lines, improved instrument lifespan, reduced maintenance costs, and highly reproducible analytical results.

Available in standard and custom configurations with international safety certifications, the Gas Purification Panel & Control System is your dependable partner for demanding laboratory environments.

Key Features :

- High-Grade Construction: Powder-coated wall-mounted panel with optional full stainless-steel body for enhanced durability and corrosion resistance.

- Precision Gas Purification: Removes moisture, oxygen, hydrocarbons, and particulates to deliver better-than-UHP-grade gases.

- Integrated Safety: Optional safety frames, CE-certified designs, and leak-tight sealing to ensure operator and system safety.

- Flexible Pressure Control: Supports 10 kg/cm² inlet pressure with adjustable 0–7 kg/cm² outlet via precision regulators.

- Easy Serviceability: Modular, easily detachable filters enable hassle-free maintenance and replacement.

- Cost-Effective Operation: Toggle valves and distribution panels reduce gas wastage and optimize usage.

- Customizable Connectivity: Available with 1/4” or 1/8” fittings and tubing in SS, Copper, Nylon, or Teflon.

Applications

Gas Chromatography

(GC)

ICP & AAS

Systems

LC-MS-MS Exhaust Systems

General Laboratory Gas Delivery

Product Models & Specifications

|

Model Name |

Dimensions (mm) |

Weight |

Inlet Pressure |

Outlet Pressure |

Connections |

|---|---|---|---|---|---|

| GPP-01 | 420 W × 600 H × 87 D | 14 kg | Up to 10 kg/cm² | 0–7 kg/cm² | 1/4” or 1/8” tubing |

Laboratories & Research Centers

- Inlet pressure: 10 kg/cm² maximum

- Outlet range: 0–7 kg/cm² with Neoprene/SS diaphragm

- Toggle Valve: On/off type with leak-tight dual-seal design

- Pressure Gauges: Panel-mounted, 0–10 kg/cm²

Tubing Options:

- Materials: Stainless Steel, Copper, Nylon, Teflon

- Smooth bore construction with color-coded sleeves for contamination-free gas flow

Filtration & Purification Stages

- Moisture Removal: Indicating silica gel and molecular sieves (outlet impurity < 3 ppm)

- Oxygen Removal: De-Oxo catalytic materials (outlet impurity < 2 ppm)

- Hydrocarbon Removal: Activated charcoal/carbon filters (outlet impurity < 2 ppm)

- Particulate Removal: Inline stainless-steel micron filters (5–10 µ)

Additional Technical Highlights

Inline Micron Filters:

Essential for capturing fine particles shed by cylinders, protecting sensitive GC detectors.

Activated Charcoal Cartridges:

High-surface-area media for hydrocarbon removal, reducing FID baseline noise.

Silica Gel & Molecular Sieves:

High-capacity, regenerable, with indicating color change for easy monitoring.

De-Oxo Catalysts:

Pre-treated, regenerable, available in indicating/non-indicating options.

Integrated Distribution Panels:

Control gas flow and pressure to multiple instruments with independent settings.

Selector and Changeover Boxes:

Seamless switching between cylinders or gas generators for uninterrupted supply.

Why Choose Athena Instruments Gas Purification Panel & Control System?

Precision Purification

Delivers contamination-free UHP gases essential for accurate, reproducible analysis.

Cost-Efficient Operation

Reduces high-purity gas consumption with precision control and efficient distribution.

Customizable Configurations

Built to your specifications with flexible fittings, tubing, and filtration options.

Responsive Support

Backed by Athena’s technical assistance, including remote and on-site service options.

Enhanced Instrument Life

Protects sensitive GC columns and detectors from moisture, oxygen, hydrocarbons, and particulates.

Field-Proven Durability

Designed for rugged lab environments with high-quality materials and components.

Certified Quality

CE certified, ISO 9001:2015 compliant for global safety and quality standards.